The horizontal ribbon blender

The horizontal ribbon blender

Horizontal ribbon blender is a kind of ribbon blender, it’s suitable for sticky or cohesive powder mixing, and adding to liquid and paste materilas.

A. The introduction of The horizontal ribbon blender:

1.The horizontal ribbon blender consists of U-shaped containers, ribbon mixing blade and transmission components; ribbon points continuous and disconnect the helical ribbon blaze is generally made of a double or triple outer spiral the materials from both sidesbrings together the central inner spiral the material transported from the center to the sides to from a stream mixed.

2.Adding a liquid and pasty materials mixed in the ribbon mixer for viscous or cohesive granule mixing and granule has a good effect, cylinder cover can be made of a wide-open door, so that the equipment for cleaning.

3.Can be added to the mixer barrel outer jacket,cooling or heating of the material is achineved by injecting the cooling medium to the jacket;

4.Discharge generally in the form of a pneumatic flap valve(manual), the arc valve compact embedding barrel, flush with the tube wall, the phenomenon of materila accumulation and mixing dead ends, reliable trim seal, frequent switch leakage.

horizontal ribbon blender

B. The Features:

1) With large loading coefficient,the equipment covers in small area.

2) It’s difficult to clean for mixing the sticky or cohesive materials.

horizontal ribbon blender

C. The Work characteristics:

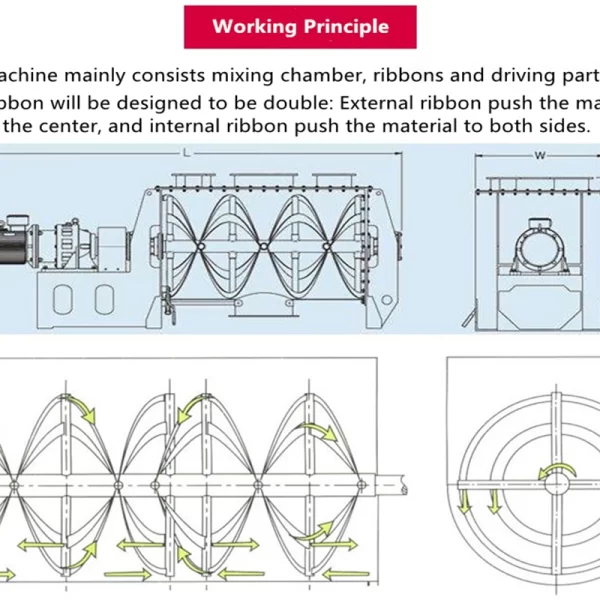

1) The horizontal ribbon mixer is Driven by a motor through a reduction of the special arrangement of ribbon spindle rotation.outer ribbon put the material to the center of machine, inner ribbon push the material to a certain position or plates,both of them can make materials to mutual diffusion,convection, shear, dislocation and radial movement,to achieve a steady mixing performance in a short time.

2) There are three stirring way with standard design.continuous ribbon,Interrupter ribbon,and blaze can be chosen,they were arranged on the requirements of the center or bottom discharge materials.

ribbon blender

D. The discharge structure:

With the discharge form of manual flap valve, the arc valve is tightly embedded inner cylinder, without dead

material accumulation and mixing phenomenon. Reliable edge of the seal, ensure frequent leaks at the beginning

Ribbon Blender working Principle

Ribbon blenders are a specific type of powder mixer blenders that consist of 2 parts mounted on a central shaft . The mixing medium often consists of inner and outer helical ribbon blades that are designed to move products both inwards and outwards direction. The external helical ribbon blade pull material from the sides of the mixer into the middle and the internal ribbon blade push the material back to the sides. The back-and-forth folding motion of the materials to be blended creates a convective mixing pattern.

The ribbon blades are designed to have precise gap tolerances between the walls of the mixer. In some instances, they can even be designed with soft material wipers to help keep product from building up on the sides. The drive mechanism often consists of a belt drive for the powder transmission between the motor and gear box. This arrangement would use a system of flexible belts and pulleys to produce the desired speed and torque required for the specific mixing application. However, more manufacturers are starting to use direct drives via gear motors that utilize a motors low inertia rotor to specifically match the gearbox unit. The advantage of this arrangement means less maintenance over the life of the industrial mixer.

Make sure to understand the required volume capacity of the mixer you are in need of. Knowing the bulk densities of the ingredients to be mixed is crucial to understanding the required capacity of your mixer, and more importantly the needed motor power required to mix your batches properly. Most standard design mixers will work just fine with a product bulk density of 35 lbs./ft³. However, once you start mixing denser batches the need for heavy duty motors and gear ratio changes will also be required.

2. Main benefits of ribbon blenders

Ribbon mixers are the most versatile and widely used type of powder blending machine in the market. They often are most commonly used for solids on solids mixing but can also be used for applications involving coating a dry particle with a liquid ingredient, or even particle absorption of a liquid addition. Rarer applications do allow for slurry and liquid particle suspension mixes with careful design and consideration to detail.

Because of the convective mixing pattern of the ribbon blender, short and fast mixing cycles are possible often ranging from a few minutes up to 20 minutes (depending on the volume and complexity of the formula). Considering the fast-mixing cycles of these bulk solids blenders you would think the ribbons run at a very high RPM, however this is not so. The ribbon agitators typically run no faster then 300 feet/min tip speed. This low speed creates a gentle folding action of the particles to be mixed. Therefore, this allows use on fragile and friable materials while preserving the particle integrity.