About Explosion-proof Reactor

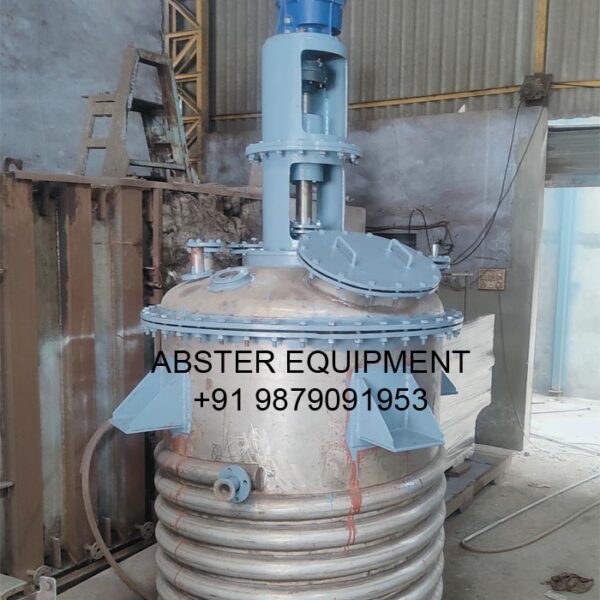

Reactor:

ss-reactor-polyester resin kettle, Grease Kettle

What designd enable explosion-proof reactor to provide higher safet when handling flammable and explosive materials?

1. Explosion-proof Electrical System

Explosion-proof reactor is equipped with explosion-proof motors, explision-proof controllers and explision-proof sensors. All electrical components are explosion-proof to avoid explosions caused by electric sparks or overheating.

2. Electrostatic Protection

By adding grounding devices inside and outside the equipment, static electricity is prevented from accumulating and the risk of sparks is reduced.

3. Safety Valves and Bursting Discs

Overpressure protection devices such as safety valves and bursting discs are installed. When the pressure in the reactor increases abnormally, the pressure can be quickly released to prevent the equipment from bursting.

4. Nitrogen Protection System

For materials that are prone to oxidation reactions, the explosion-proof reactor can be equipped with a nitrogen protection system. By filling in inert gas to isolate the air, oxygen can be prevented from causing combustion or explosion.

5. Pressure-resistant Design

Explosion-proof reactor is made of high-strength materials, and the reactor body can withstand high pressure to prevent bursting under high-pressure conditions.

6. Temperature Control System

Equipped with a precise temperature control and monitoring system to prevent abnormal temperature increases, thereby causing thermal runaway and explosion.

7. Sealing Design

Use high-performance sealing materials and structures to prevent leakage of flammable and explosive gases while maintaining the airtightness of the reaction environment.

reactor

Tags: reactor, chemical reactor