Ribbon blenders are widely used for homogeneous mixing of dry granules & powders. The blender comprises a ‘U’ shaft with two sets of spiral ribbons, one inside the other. Inner and outer ribbons are perfectly arranged, that during rotation, the material reaches each corner of the trough and imparts radial & linear motion to the whole of the material to be mixed. Our range of ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending.

Ribbon Blender Operations:

- The complete assembly is mounted on a MS/ SS structure

- The material is moved from side of the trough to the centre and vice versa resulting in quick & homogeneous mixing

- Double ribbon configuration also brings material towards central bottom outlet while discharging

- A specially designed valve is provided at the center or butterfly valve for discharge

- Blending is achieved in semi-fluidized state in the upper zone of the trough when used for fine powders

- Machine can be provided with spray nozzles with pressure spraying system for spraying additives in blenders

- Ribbon blender can also be used as dryer by providing jacket on the trough

- All contact parts in SS 304/ SS 316 quality

- Ribbon Blender Mixer comes in Standard and GMP models specially designed flush type outlet valve or butterfly valve (optional)

- Top cover with acrylic sheet

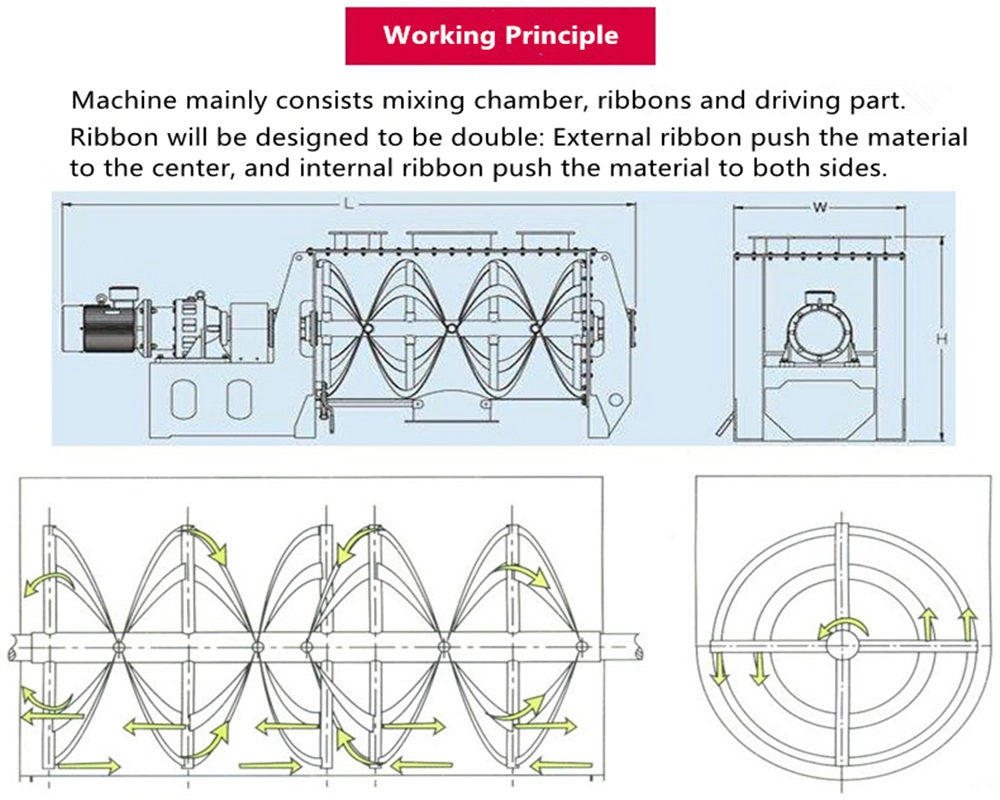

Ribbon Blender Working Principle:

The outer ribbon combined with rotating direction drives material from two sides to the center, meanwhile inner ribbon drives material from center to two sides, and the high speed chopper blades could break and disperse the lumps and blocking.

Therefore horizontal double ribbon mixer with crushing chopper blades can especially meet the demands of various kinds of blending powdery materials which may easily gather together during the mixing process. Horizontal ribbon blender machine with high speed choppers is your best choice for mixing and blending powdery materials, liquid and powder.

Double helical ribbon mixer for powder mixing and liquid spray system is featured with shorter mixing time and better blending uniformity.

Ribbon Blender Capacity Table

| Model | Gross Volume approx. | Working Volume approx. | Power |

| RM-10 | 10 Liters | 5 Liters | 0.5 H.P. |

| RM-50 | 50 Liters | 20 Liters | 1 H.P. |

| RM-75 | 75 Liters | 50 Liters | 1 H.P. |

| RM-150 | 150 Liters | 100 Liters | 2 H.P. |

| RM-250 | 250 Liters | 150 Liters | 3 H.P. |

| RM-450 | 450 Liters | 300 Liters | 5 H.P. |

| RM-600 | 600 Liters | 450 Liters | 7.5 H.P. |

| RM-1100 | 1100 Liters | 750 Liters | 10 H.P. |

| RM-1500 | 1500 Liters | 1000 Liters | 12.5 H.P. |

| RM-2000 | 2000 Liters | 1250 Liters | 15 H.P. |

| RM-3000 | 3000 Liters | 1875 Liters | 20 H.P. |

| RM-5000 | 5000 Liters | 3000 Liters | 25 H.P. |

| RM-10000 | 10000 Liters | 6000 Liters | 40 H.P. |